In the field of industrial equipment after-sales service, customers' most urgent needs are 'instant response and quick resolution', while service teams have long faced the pressure of frequent repetitive inquiries and high travel costs. The traditional 'phone description + engineer dispatch' model can no longer meet the expectations for service efficiency in the digital age. The deep application of 3D animation technology is bringing revolutionary changes to this field – by building a complete visual self-service system, it achieves a 'zero wait' customer service experience and liberates the service team from repetitive work.

Building a 'Visual Knowledge Base': Transforming Expert Experience into Shared Assets

The core value of 3D animation lies in its ability to transform the implicit knowledge of senior engineers into explicit knowledge that customers can access anytime. By creating precise animated content for key knowledge such as equipment operation, maintenance procedures, and fault diagnosis, companies are essentially building an 'always-on visual knowledge base'.

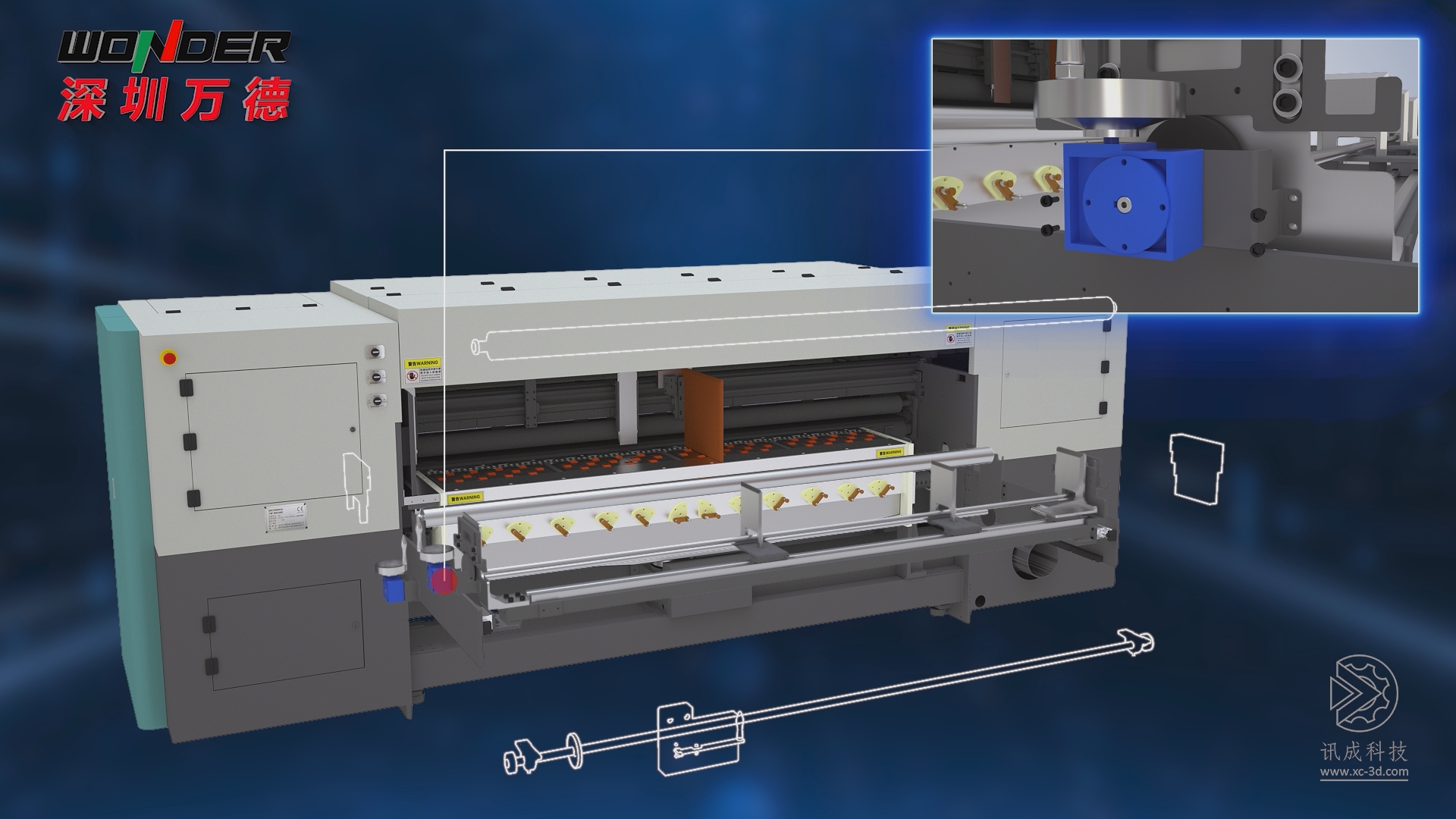

The practice of Shenzhen Wande Digital Technology Co., Ltd. fully embodies this value. The company has developed a complete set of 3D animations for its digital printing machines covering operation, maintenance, and wear part replacement, supporting multiple languages and convenient use on tablet devices. This system enables customers to independently perform over 70% of routine maintenance, reducing average repair time by 40%, and significantly lowering travel and labor costs for the service team. Customers do not need to wait for engineers to arrive, and the service team can focus their energy on more complex fault troubleshooting.

Precise Guidance Replaces Vague Descriptions: Eliminating Communication Errors

In traditional phone support, customer descriptions of faults and engineers' understanding often differ, leading to multiple back-and-forth communications or incorrect diagnoses. 3D animation, through standardization and visualization, presents fault phenomena, diagnostic steps, and repair methods in the most intuitive way, completely eliminating the uncertainty brought by verbal descriptions.

Foshan Jinbing Machinery Co., Ltd. uses 3D animation to precisely mark maintenance points and wear part locations, breaking down complex maintenance procedures into simple and clear steps. This 'visual operation' model not only overcomes language barriers for international customers but also transforms maintenance tasks traditionally performed by professionals into standard operations that customers can complete independently, achieving optimal allocation of service resources.

Proactive Maintenance Guidance: Eliminating Problems Before They Occur

The most efficient service is preventing problems from occurring. 3D animation can visually display key monitoring points and predictive maintenance indicators of equipment, guiding customers to detect signs of issues promptly during daily operations and take preventive measures, thereby avoiding small problems from escalating into major failures.

Ruichang Carton Machinery Manufacturing Co., Ltd.'s 3D animation training system, by simulating precursor phenomena before common faults occur, guides operators to identify early warning signals. This proactive guidance has helped customers reduce unexpected downtime incidents by over 50%, thereby increasing customer production efficiency and significantly reducing the emergency response pressure on the service team.

Data-Driven Service Optimization: From Reactive Response to Proactive Improvement

The digital nature of 3D animation systems also provides companies with valuable user behavior data. By analyzing customer access patterns to different animated content, companies can accurately identify common product issues and knowledge gaps, thereby optimizing product design and service systems.

Through analysis, the service team discovered that a specific fault diagnosis animation was frequently accessed, leading them to identify a particular design flaw in the product. This data-driven insight not only guided the focus of after-sales service investment but also provided clear direction for the product department, achieving a virtuous cycle of reducing service demand at the source.

Building a Win-Win Situation: Enhancing Customer Capabilities, Focusing on Professional Value

When customers can independently solve most routine problems through 3D animation, the role of the service team also upgrades – shifting from repetitive on-site service to high-value technical support, remote diagnostics, and system optimization. This transformation enhances customers' technical capabilities and autonomy, while allowing the service team to fully leverage their professional value.

The experience of Xiamen Sanlei Packaging Material Co., Ltd. shows that after introducing 3D interactive animation, service engineers can dedicate more time to creative work such as equipment optimization and process improvement. This role shift not only enhances customer production efficiency but also boosts engineers' job satisfaction and opens up new avenues for service value creation for the company.

3D animation is reshaping the value logic of industrial equipment services. By building a visual knowledge system, precise operational guidance, predictive maintenance support, and data-driven optimization, it achieves a paradigm shift in customer service from 'passive waiting' to 'self-resolution'. This transformation not only brings a 'zero wait' customer experience and significantly reduced service costs but, more profoundly, redefines the relationship between manufacturers and customers – upgrading from traditional dependency-based service to an empowering partnership. In the new era where service is competitiveness, investing in 3D animation self-service systems is no longer just a technical choice for improving service efficiency, but a strategic measure for building sustainable competitive advantage.

Featured FAQs:

Q: What categories does Xuncheng's animation video production include?

A: Animation video production includes the following three categories:

Promotional: Including product promotion, corporate promotion, etc.

Technical: Including equipment operation, equipment maintenance, equipment repair, wear part replacement, equipment assembly, equipment safety, etc.

Customized: Including exhibition videos, investment promotion videos, event warm-up videos, etc.

Q: Will equipment operation animations expose sensitive structures of the equipment?

A: No.

Equipment operation animations demonstrate the content of traditional paper operation manuals in video format (e.g., in printing machines, the paper feeding unit mainly explains how to adjust baffles and guides, and how to load paper; the printing unit mainly explains how to ink, change plates, and adjust printing pressure, none of which involve sensitive equipment structures). Machine manufacturers can also delete or deform sensitive equipment structures when providing equipment models.

The control always remains with the machine manufacturer.

Q: Are equipment operation animations very expensive?

A: Let's start with the conclusion: Equipment operation animations create benefits for machine manufacturers. The greater the investment, the greater the return.

The cost of producing equipment operation animations generally ranges from tens of thousands to over a hundred thousand, or even higher. While seemingly expensive, the average cost per machine is not high.

How do equipment operation animations create benefits for machine manufacturers?

1- Low average cost. Machines are generally updated slightly every 2 years and significantly every 4 years. The total cost of animation video production is very low when averaged per machine;

2- Equipment premium. According to actual test data from machine manufacturers, for every 1 yuan invested in creating equipment operation and maintenance animations, the equipment sales premium generated is approximately 3-5 yuan, i.e., a 3-5 fold return);

3- Significantly reduces after-sales service costs, especially during the equipment warranty period;

4- Effectively increases customer loyalty;

5- More competitive compared to similar products.

Characteristics: Significant upfront investment, very small subsequent investment.

About Xuncheng Technology

Founded in 2016, with 9 years of professional industrial 3D animation creation experience, our clients include startups, overseas businesses, listed companies, and foreign-invested enterprises. We specialize in providing 3D animation creation for mechanical equipment, high-tech industries, software development, and foreign trade companies. We offer one-stop industrial 3D animation creative services, from product sales to after-sales maintenance.

We have provided nearly 3,000 minutes of professional animated videos for over 200 manufacturing enterprises.

Whether at trade shows or client visits, whether expanding into overseas markets or enhancing after-sales service, we firmly believe that through the power of design, complex products and machinery can be presented in stunning 3D animation. This not only brings a unique visual experience to clients but also quickly wins their hearts.